- New

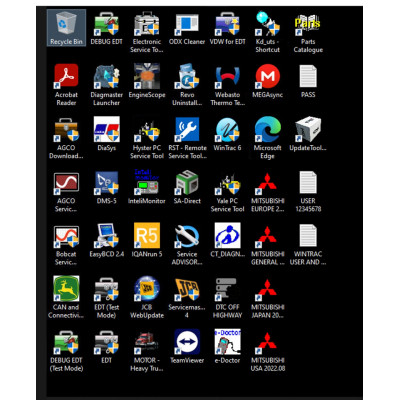

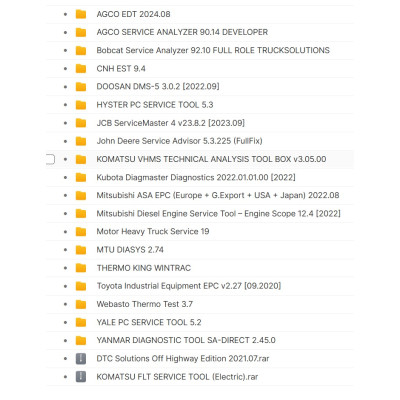

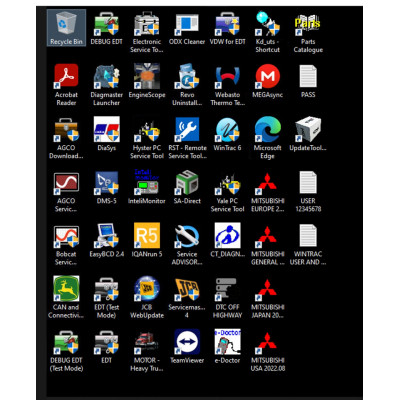

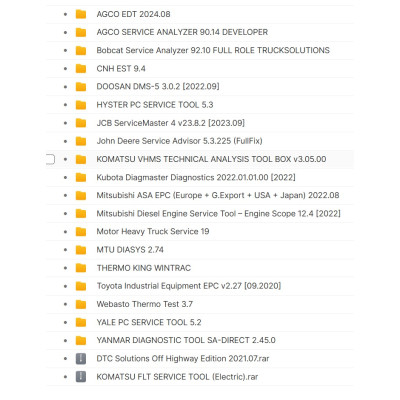

Our specialized computer installation package provides an all-in-one diagnostic and maintenance solution for heavy machinery, agricultural equipment, forklifts, and industrial vehicles. By including powerful software like AGCO EDT 2024.08, Case Service Analyzer 90.14, Bobcat Service Analyzer 92.10, Doosan DMS-5 3.0.2 (2022), and more, this suite helps technicians quickly identify and fix issues, streamline routine maintenance, and minimize downtime—ultimately saving you both time and money.

Are you looking for professional diagnostic and repair solutions for construction machinery, agricultural machinery, forklifts and heavy equipment? The computer installation package with the following top software series is the optimal choice for you:

AGCO EDT 2024.08

Case Service Analyzer 90.14

Bobcat Service Analyzer 92.10 FULL ROLE TROUBLES

Doosan DMS-5 3.0.2 (2022)

Hyster PC Service Tool 5.3

JCB ServiceMaster 4 v23.2 & 1.82

John Deere Service Advisor 5.3.2023

Kubota Diagnostic Tool

Mitsubishi ASA EPC (Europe & Export + USA + Japan 2022)

Mitsubishi Diesel Engine Service Tool

Motr Heavy Truck Service 19

MTU DIASYS 2

Thermo King Wintrac

Toyota Industrial Equipment EPC v2.2023

And many other specialized software...

This solution set not only supports checking, troubleshooting, and detailed diagnosis but also helps update data and perform effective maintenance for most machine models. With a friendly interface, superior features and in-depth data warehouse, this software suite helps technicians save time, reduce costs and improve work efficiency. Contact us now for detailed advice and own a powerful computer installation package, helping your business operate equipment optimally!

Based on the software tools listed, here are the minimum (and recommended) system requirements for installing and running the diagnostic software package for heavy machinery, agricultural equipment, forklifts, and industrial vehicles:

1. Operating System (OS)

2. Processor (CPU)

3. Memory (RAM)

4. Storage

5. Display Resolution

6. Additional Software Requirements

7. Network Connectivity

This configuration will help ensure that you can install and run the entire suite of diagnostic software reliably, minimizing downtime and boosting operational efficiency.

Adapter Connectivity Requirements

In addition to the computer hardware and software setup, using the full suite of diagnostic tools requires the appropriate connectivity adapters to interface with various heavy machinery systems. Here are the key adapter requirements:

Multi-Protocol Support:

Ensure your adapter supports multiple communication protocols (e.g., OBD-II, CAN bus, K-line, J1939) to connect with different equipment from various manufacturers.

USB Interface:

Most modern adapters connect via USB (preferably USB 3.0 for faster data transfer). Verify that the adapter is compatible with Windows 10/11 and includes up-to-date drivers.

Serial and Ethernet Options:

Some machines may still use RS232/serial ports or require an Ethernet connection. An adapter that offers both USB-to-serial and Ethernet connectivity can cover these scenarios.

Wireless Capability:

For certain diagnostics that support remote or wireless access, consider an adapter with Wi-Fi or Bluetooth functionality. This is especially useful in environments where cables can be cumbersome.

Proprietary Connectors:

Many heavy machinery manufacturers use proprietary diagnostic ports. Ensure that the adapter or adapter kit you select includes connectors or cables tailored for brands like AGCO, Case, Bobcat, John Deere, Kubota, Mitsubishi, and others.

Robust and Industrial-Grade Design:

Given the industrial environment, choose adapters designed to withstand harsh conditions. Look for ruggedized options that offer reliable performance, high-speed data transmission, and compatibility with the entire diagnostic software suite.

By ensuring that you have the correct adapters, you can seamlessly integrate and utilize all the diagnostic tools included in your installation package, leading to more accurate fault diagnosis, efficient maintenance, and reduced downtime.

No customer reviews for the moment.

Contact us on WhatsApp!